“A fully automated horizontal baler” may sound like a huge piece of equipment and create a notion of an application only for municipalities or recycling centers. However, horizontal balers come in different sizes and a fully automated solution can very well be feasible and the preferred option to streamline waste handling for retailers, factories and warehouses.

Sure, we are all looking for the most convenient and less work-intensive solution

When facing a challenge at work and trying to find a smart, cost-effective and good long-term solution to it, it can be difficult to know where to start. One such challenge is organizing the stream of packaging material and the waste management in a business. No matter what your core business is, if you mainly produce, sell or store goods, there are often big volumes of empty packaging material to handle. If you are a production manager, a store manager or a warehouse manager that project may have ended up on your table.

When first looking into it, there seem to be many factors to consider and alternatives available – different types of equipment and logistics options, but to be honest we are all looking for the most convenient and less work-intensive solution. It is not about being lazy, it is about being rational. A fully automated solution that, once it is set up, is in operation and does its job without demanding manual work from the staff is efficient. Your staff can use its time more productively focusing on the core business instead of spending time on waste handling.

A long row of neat and compact bales

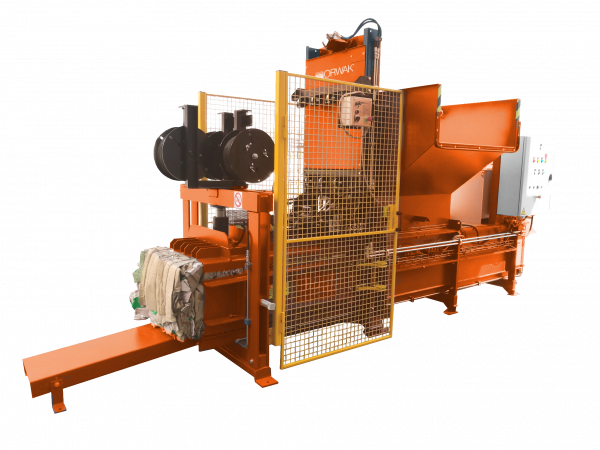

A fully automated horizontal baler is one such solution – a complete system where the packaging material is compacted, cut and baled. A horizontal baler can be fed manually or by regular bins and a bin lifter, but there are also ways to automate even the infeed by for example adding a conveyor belt or connect it to an air transport system.

The required bale length is selected in the settings and the bale binding is also automated. The machine produces a long row of neat and compact standard bales that can be easily removed by forklift or picked up directly by a logistics company.

If the horizontal baler has capacity to generate mill-size bales, you can sell the bales directly to a paper mill or a plastic processing plant. That is a way to turn the waste handling cost into an income!

Automated solution does not mean big and space demanding

When you have come this far in the consideration process, you may think that an automated horizontal baler is a great thing to have in your business, but that a machine with all those functions probably is very big and space demanding, but that must not be the case. Thanks to smart design and modern technology a fully automated horizontal baler can be very compact. Small models take up less floor space than a 20’ container and can easily be placed indoors in your storage area or warehouse. To facilitate internal logistics small models can often be delivered in several parts.

Even if you need a bigger horizontal baler model to master the volumes of recyclable paper-based or plastic packing material in your organization, compare its footprint with the space the current solution – for example containers of uncompacted material – takes up.

Horizontal balers quickly minimize the material in a cost-effective way and at the same time contribute to improving the internal and external logistics, more productive work and even an increased income when delivering high-quality bales directly to the recycling industry. Generating and saving money through recycling leads to rapid system payback.

Orwak provides a wide range of fully automated horizontal balers and you are welcome to contact us for advice and more details about large-scale waste handling solutions. We have international sales and service teams ready to serve you locally in many countries.